Eli Terry patent wood-works, mass-produced mantle clock c1830

Eli Terry patent wood-works, mass-produced mantle clock c1830 (Draft)

?? means I need to check the information or to write some more!Eli Terry was a pioneer of the mass production of clocks via inter-changeable parts in the early 1800s. He was in relative isolation from mainstream clock making being in Connecticut, USA, rather than England or Europe. The isolation allowed the innovation; he may have had trouble doing it in England against the might of the Clockmakers Guild. I will discuss this more in another post.

The movements were initially made of wood as the machinery was available and it kept costs down. Metal machining was mainly done by hand. The screw-cutting metal lathe, with a fixed tool post, was developed in the early 1800s by Henry Maudsley in England. It was to go on to underpin the production of machine tools for the industrial revolution in England. The American clocks were mass-produced from metal from the mid-1800s.

Terry saw an opportunity in producing low-cost clocks for ordinary American families. A mantle clock was preferred over a long-case, grandfather clock as space was at a premium in small houses. Mantle clocks suited the available means of sale and distribution, peddlers, who had limited space on their wagons.

The clocks were reasonably accurate for their time and only needed winding each week. Suspended weights and a pendulum contribute to accuracy. With a mantle clock, the weights are suspended beside the clock rather than under it as in a long case clock. Escapement?? other technical bits?? While an early mass-produced clock, they had a chime and associated weight and wheel train, an extra level of complication and sophistication for a wood-works clock. As the pendulum is shorter in a mantle clock compared to a long-case clock, the beat is faster??

Eli Terry Sr. patented his clock and licensed it to other clockmakers. My clock is manufactured by his son, Eli Terry Jr. c1830. Eli Terry Jnr. produced around 10,000 clocks each year. In contrast, the English clockmaker of my marine chronometer handmade 11 in 1917.

??

Home

My unrestored Eli Terry Jr. patent wood-works clock c1825.

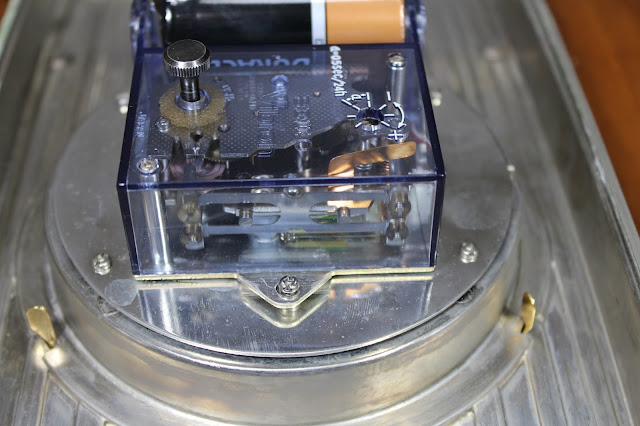

The wooden movement with a strike or chime wheel train and a recoil escapement. The escapement drives the pendulum and the pendulum swing determines the time. The slotted wheel is part of the chime. The hammer hits a coiled wire for the chime. A wooden case gives pleasant reverberation and richness to the chime.

Eli Terry's patent label. Instructions too, itself a first.

The weight arrangement for Eli Terry patent clocks. The pendulum is missing. The photo is from another clock produced under licence by a different maker (pending me fixing up my clock??)

The pendulum suspension and drive or impulse from the escapement. Another clock.

The two wheel trains, time and strike, of another Eli Terry patent clock. I was surprised that wooden wheels could work so well and be mass produced. The escape wheel is the only one of metal, but it turns the most and is critical for correct angles.

https://en.wikipedia.org/wiki/Eli_Terry

https://en.wikipedia.org/wiki/Henry_Maudsley

http://www.newenglandhistoricalsociety.com/eli-terry-connecticut-clock-maker/

Comments

Post a Comment